Blog

Tracking and Right-Sizing Your Fleet

Back to Blog(s)

June 25 2024

June 25 2024

How Connected Assets Enable Ideal Facility Operations

![]()

It may seem like the dream of a distant future, but robot fleets are starting to become a “thing” for those who work in the facilities management field. Sounds scary? It might, if the term “robot fleet” conjures images of a malevolent robot army hellbent on coldblooded destruction. The reality is a lot less dramatic, far more useful, and actually, quite a bit more human.

So what exactly is a robot fleet? In the realm of facilities management, a robot fleet is a collection of on-premise, task-performing robots that are ideally tracked, coordinated and managed by a unified software platform, or FMS. Within facilities management, the integration of robot fleets for tasks such as automated floor cleaning, supply delivery, disinfection, and even visitor assistance, is rapidly transforming the way organizations oversee and optimize their operations.

With this transformation comes questions about the best way to manage not only growing robot fleets, but other assets routinely used in facility management operations, such as autoscrubbers, vacuums, IoT sensors and more. Let’s take a look at some of the novel solutions rising to meet the needs of robot fleet management.

Robust Facility Management Systems

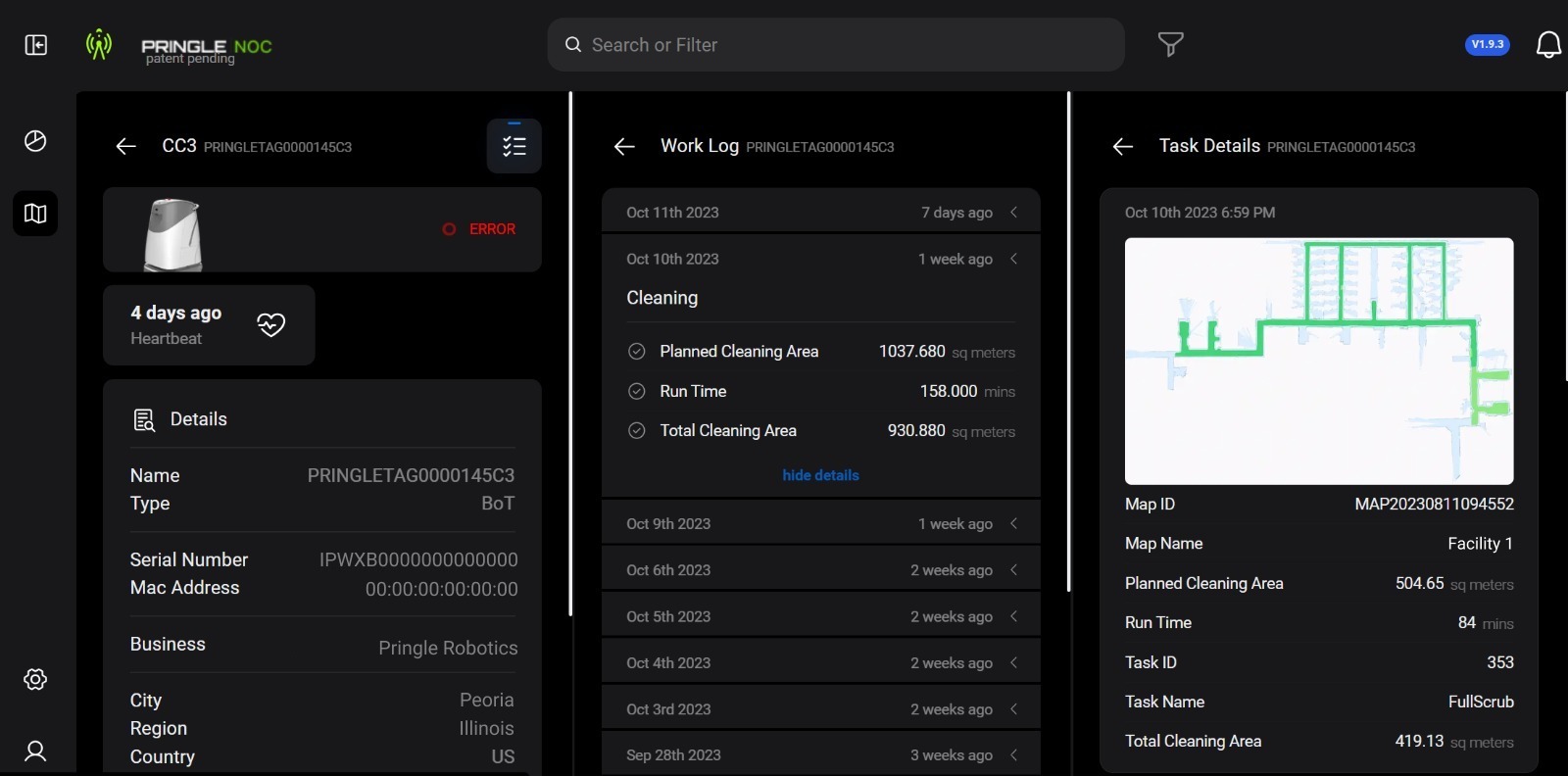

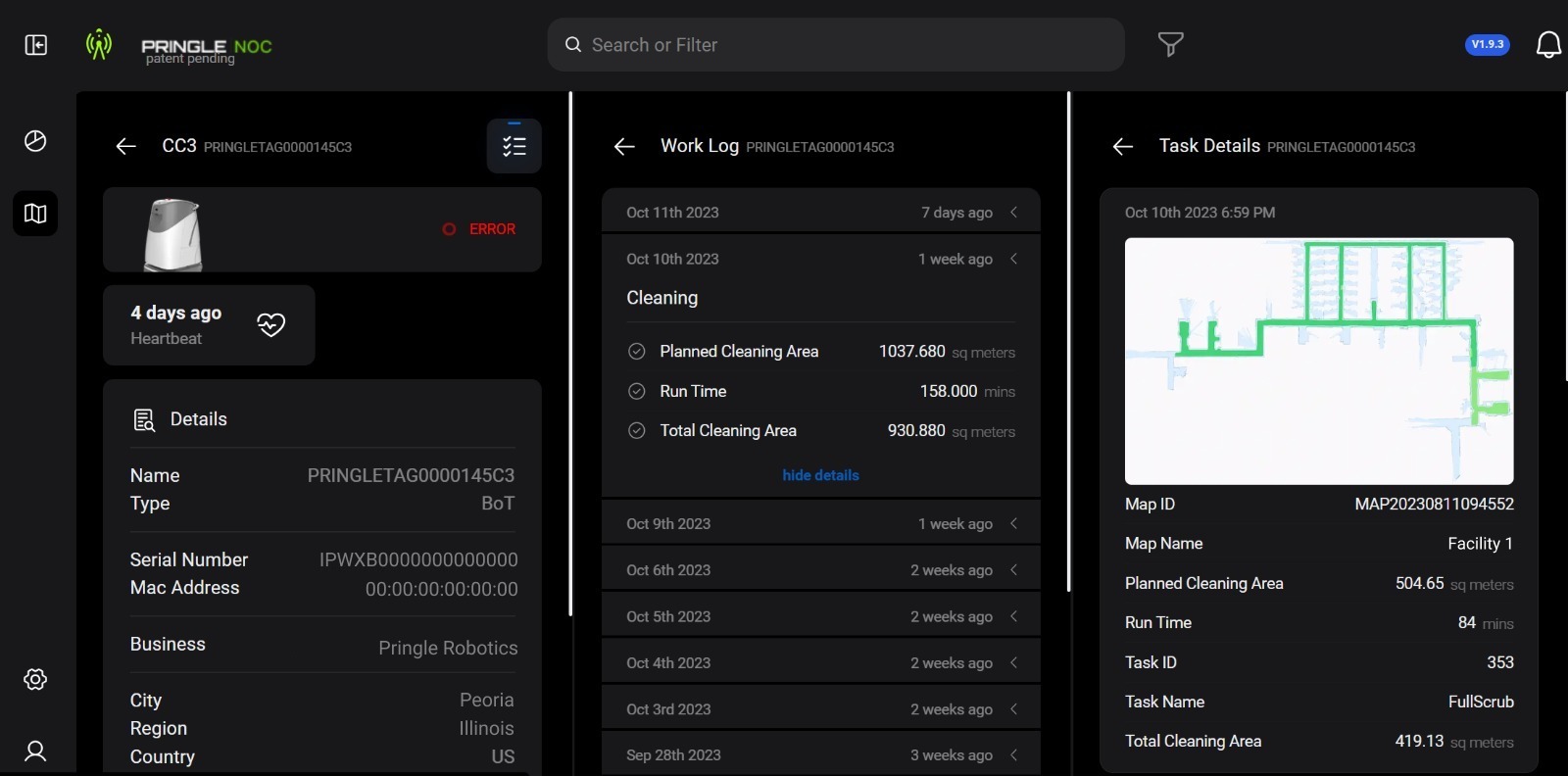

A Facility Management System (FMS) is a unified software solution that allows facilities to manage their physical assets, spaces, cleaning/maintenance and workflows through one centralized hub. For robot fleets in particular, a good FMS ensures that a facility’s robots are

not merely standalone assets, but actively monitored and managed components of a unified system. For instance, systems like Pringle NOC and Pringle Pristine within the Pringle FMS Ecosystem enable:

- Real-time tracking and control, so facility managers can monitor robot location, status, and performance data in real time, optimizing deployments and resource allocation.

- Scheduling and task management, allowing managers to create and assign cleaning, delivery, and maintenance tasks efficiently, ensuring seamless operation and maximum productivity.

- Data analytics and reporting, providing valuable insights into robot performance, cleaning effectiveness, and resource utilization, driving continuous improvement.

- Integration of robots within existing building systems, such as elevators and access control, for unified facility management.

Not Just Robots

Robots aren’t the only physical assets whose incorporation into an FMS provides benefits. Long before most organizations were even thinking about managing fleets of cleaning or delivery robots, facility managers were tasked with managing the use and life cycle of myriad pieces of cleaning equipment. In recent years, this monitoring and management has become data-enabled and digitized thanks to innovations in telematics–the same type of technology that enables the recording and transmission of vehicular data.

Our partner, ARMOR Asset Management, has specialized in the development of asset management devices for the facilities and logistics industries since 2011. Cleaning equipment running the gamut from commercial vacuum cleaners, to floor polishers, to large ride-on or walk-behind scrubbers can easily be fitted with these IoT-connected devices to track and measure metrics like run time, power usage, charge time, location and battery life.

Why is this type of information useful?

Assurance of Cleaning

When the data provided by asset management devices is readily accessible through an FMS, there’s no longer any question about whether a machine is being used according to predetermined workflows, schedules and SOPs. The data will clearly show when a machine was run and for how long, providing insight and assurance of cleaning activity, or alerting managers of work that is falling through the cracks.

Planned and Preventative Maintenance

Much like service notifications on your car, the data collected by asset management devices allows for advance planning of maintenance on connected machines. Instead of blindly operating a machine until it runs into problems caused by deferred maintenance, FMS integration of equipment allows for not only active monitoring, but the creation of algorithms that trigger maintenance alerts well before problems start. This ensures continued machine health for efficient operations.

Capital Planning

By tracking and analyzing usage and performance data from a fleet of machines, facility managers can make informed decisions about equipment life cycles and replacement needs, as well as projections for future additions to the fleet. This type of monitoring can be especially helpful for lithium battery powered machines, as often, these batteries will outlive other physical components of the machines and can be transferred to new equipment, reducing costs. The monitoring can also alert managers to a battery nearing end-of-life, and track the proper EPA-approved disposal of said batteries once they are ready for recycling.

A Unified Solution

The potential for connectivity of multiple types of assets—from autonomous floor cleaning robots, to human-operated cleaning equipment, to myriad IoT sensors for facility homeostasis—opens up a whole new realm of possibilities in facilities management. With a unified FMS like Pringle NOC, facility managers gain total transparency into the use, operation and longevity of connected equipment, plus deep insights into space usage and internal building systems through IoT sensor data. Using a unified approach to facility and asset management, a can achieve unprecedented levels of control over daily operations as:

- Cleaning reports and “health” data provided by floor cleaning robots and delivery robots get integrated into the FMS in real time.

- Other cleaning equipment and physical assets are continually tracked and monitored through telematics devices connected to the FMS.

- IoT sensor data is readily available in the FMS and can be analyzed for immediate action or historical trends to adjust workflows.

- Standard daily tasks can be created and pushed through to assigned staff via an FMS-integrated task management app such as Pringle Pristine. These task lists can be continuously refined based on real-time data and trends provided by robots, manual equipment, and IoT sensors in the FMS.

- Thresholds and alerts can be set within the FMS to automatically trigger new cleaning/maintenance tasks based on IoT-sensor data relating to facility user feedback, room occupancy, water detection, supply levels, etc.

These kinds of insights enable informed decision-making not only regarding the repair, replacement, or upgrade of assets, but also resource allocation more generally. As robot fleets for facility maintenance become more and more common, the insights made possible by a unified FMS can help facility managers understand the current efficiency of their fleets, pinpoint ideal scenarios for upscaling their fleets, and weigh current results against goal-based metrics.

If you’re interested in learning more about unified solutions for facilities management, get in touch today!

Leave a comment below...